| IEC 60502-1 Cables | |||

| 600/1000V, PVC Insulated Cables | 600/1000V, XLPE Insulated Cables |

IEC 60502-1 Cables

600/1000V, PVC Insulated Cables according to IEC 60502-1

600/1000V, PVC Insulated Cables according to IEC 60502-1 (armoured)

Application:

These cables are used for electricity supply in low voltage installation system, They are suitable for installation in indoors and outdoors, in cable ducts, under ground, in power and switching stations, local energy distributions, industrial plants, where there is no risk of mechanical damage.

Construction:

ConductorsCopper or Aluminium conductor, round standed or Shaped, Class 2 to IEC 60228, BS EN 60228. For smaller sizes, a solid round conductor, Class 1 as per IEC 60228, BS EN 60228 can also be supplied upon request.

InsulationPVC Insulation material and thickness shall be as per IEC 60502-1 and BS 6346. PVC material shall be Type A as per IEC 60502-1 or TI1 as per BS EN 50363. PVC Insulation material as per SASO 1694 rated for 85°C continuous operation is also available upon special request.

Colour Code |

Colour Code (1) : |

||

|

1 Core |

: |

Red or Black |

|

2 Cores |

: |

Red, Black |

|

3 Cores |

: |

Red, Yellow, Blue |

|

4 Cores |

: |

Red, Yellow, Blue, Black |

|

5 Cores |

: |

Red, Yellow, Blue, Black, Green |

|

Above 5 Cores: |

Black Cores with White numerals |

|

|

Colour Code (2) : |

|

|

|

1 Core |

: |

Brown or Blue |

|

2 Cores |

: |

Brown or Blue |

|

3 Cores |

: |

Brown, Black, Grey |

|

4 Cores |

: |

Blue, Brown, Black, Grey |

|

5 Cores |

: |

Green/Yellow, Blue, Brown, Black, Grey |

|

Above 5 Cores: |

Black Cores with White numerals |

|

Assembly / |

Two, Three or Four insulated conductors are laid-up together with non-hygroscopic |

Inner Sheath |

fillers and the assembly is bedded with an extruded layer of PVC. In case of non |

|

armoured cables, this layer may be omitted |

Armour |

Aluminum/Galvanized Steel Wires applied helically over the bedding as per IEC |

|

60502 or as per BS 5467, BS 6346. Single core cables shall be Aluminium wire |

|

armour. Aluminum/Steel Tapes applied helically over the bedding of multi-core cables |

|

as per IEC 60502. |

Outer |

Outer sheath shall be of Extruded PVC Type ST2 as per IEC 60502-1 or Type 9 as |

Sheath |

BS 6346/5467. |

|

Special type of PVC sheathing material such as Fire Retardant PVC, Anti-Termite |

|

PVC, Anti-Rodent PVC, Sunlight resistant PVC, Oil Resistant PVC are available on |

|

special request. Also, special sheathing materials such as LLDPE, MDPE, HDPE, |

|

LSF, CPE are available on request. |

Fire |

Cables can be supplied with special flame retardant PVC outer sheath to comply with |

Performance |

the flame test requirements of IEC 60332-3-22, IEC 60332-3-23 and IEC 60332-3-24, |

of Cable |

can also supply cables with Low Smoke Halogen Free (LSHF) material according to |

Sheaths |

IEC 60502-1, BS 7211, BS 6724 or other equivalent standards. |

Cable Parameters:

PVC insulation

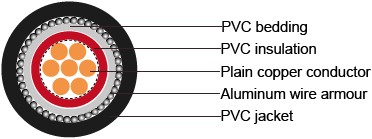

Single core( aluminum wire armoured)

Nominal Area |

Approxonductor Diameter |

Nominal Insulation thickness |

Nominal beddingthickness |

Nominal Alum Wire dia. |

Nominal Sheath thickness |

Approx.Overall Diameter |

Approx.Weight |

mm² |

mm |

mm |

mm |

mm |

mm |

mm |

Kg/Km |

1x10 |

4 |

1 |

1 |

0.8 |

1.8 |

14 |

300 |

1x16 |

5 |

1 |

1 |

0.8 |

1.8 |

15 |

375 |

1x25 |

6.3 |

1.2 |

1 |

0.8 |

1.8 |

16 |

500 |

1x35 |

7.4 |

1.2 |

1 |

0.8 |

1.8 |

18 |

625 |

1x50 |

8.8 |

1.4 |

1 |

1.25 |

1.8 |

20 |

835 |

1x70 |

10.6 |

1.4 |

1 |

1.25 |

1.8 |

22 |

1075 |

1x95 |

12.4 |

1.6 |

1 |

1.25 |

1.8 |

24 |

1385 |

1x120 |

14 |

1.6 |

1 |

1.6 |

1.8 |

26 |

1700 |

1x150 |

15.5 |

1.8 |

1 |

1.6 |

1.8 |

28 |

2025 |

1x185 |

17.4 |

2 |

1 |

1.6 |

1.8 |

31 |

2450 |

1x240 |

20.3 |

2.2 |

1 |

1.6 |

1.9 |

34 |

3100 |

1x300 |

22.7 |

2.4 |

1 |

2 |

2 |

38 |

3900 |

1x400 |

25.4 |

2.6 |

1.2 |

2 |

2.1 |

42 |

4875 |

1x500 |

28.8 |

2.8 |

1.2 |

2 |

2.2 |

45 |

6050 |

1x630 |

30.4 |

2.8 |

1.2 |

2 |

2.4 |

50 |

7625 |

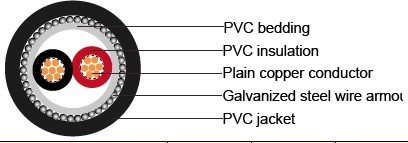

Two cores(Galvanized steel wire armoured)

Nominal Area |

Approxonductor Diameter |

Nominal Insulation thickness |

Nominal beddingthickness |

Nominal Steel Wire dia. |

Nominal Sheath thickness |

Approx.Overall Diameter |

Approx.Weight |

mm² |

mm |

mm |

mm |

mm |

mm |

mm |

Kg/Km |

2x2.5 |

2 |

0.8 |

1 |

0.8 |

1.8 |

15 |

425 |

2x4 |

2.6 |

1 |

1 |

0.8 |

1.8 |

17 |

525 |

2x6 |

3.1 |

1 |

1 |

1.25 |

1.8 |

19 |

775 |

2x10 |

4 |

1 |

1 |

1.25 |

1.8 |

20 |

825 |

2x16 |

5 |

1 |

1 |

1.25 |

1.8 |

21 |

950 |

2x25 |

6.3 |

1 |

1 |

1.25 |

1.8 |

23 |

1150 |

2x35 |

7.4 |

1.2 |

1 |

1.6 |

1.8 |

27 |

1700 |

2x2.5 |

2 |

1.2 |

1 |

1.6 |

1.8 |

29 |

2050 |

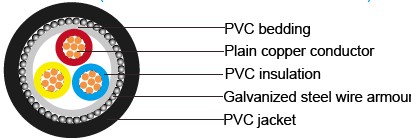

Three cores(Galvanized steel wire armoured)

Nominal Area |

Approxonductor Diameter |

Nominal Insulation thickness |

Nominal beddingthickness |

Nominal Steel Wire dia. |

Nominal Sheath thickness |

Approx.Overall Diameter |

Approx.Weight |

mm² |

mm |

mm |

mm |

mm |

mm |

mm |

Kg/Km |

3x2.5 rm |

2 |

0.8 |

1.2 |

0.8 |

1.8 |

16 |

465 |

3x4 re |

2.3 |

1 |

1.2 |

1.25 |

1.8 |

18 |

685 |

3x4 rm |

2.6 |

1 |

1.2 |

1.25 |

1.8 |

19 |

725 |

3x6 re |

2.8 |

1 |

1.2 |

1.25 |

1.8 |

19 |

800 |

3x6 rm |

3.1 |

1 |

1.2 |

1.25 |

1.8 |

20 |

850 |

3x10 re |

3.6 |

1 |

1.2 |

1.25 |

1.8 |

21 |

1000 |

3x10 rm |

4 |

1 |

1.2 |

1.25 |

1.8 |

22 |

1050 |

3x16 rm |

5 |

1 |

1.2 |

1.25 |

1.8 |

24 |

1350 |

3x25 rm |

6.3 |

1.2 |

1.2 |

1.6 |

1.8 |

29 |

1975 |

3x35 rm |

7.4 |

1.2 |

1.2 |

1.6 |

1.8 |

31 |

2300 |

Nominal Area |

Approxonductor Diameter |

Nominal Insulation thickness |

Nominal beddingthickness |

Nominal Steel Wire dia. |

Nominal Sheath thickness |

Approx.Overall Diameter |

Approx.Weight |

mm² |

mm |

mm |

mm |

mm |

mm |

mm |

Kg/Km |

3x50 sm |

- |

1.4 |

1.2 |

1.6 |

2 |

32 |

2675 |

3x70 sm |

- |

1.4 |

1.2 |

2 |

2.1 |

36 |

3700 |

3x95 sm |

- |

1.6 |

1.2 |

2 |

2.2 |

41 |

4750 |

3x120 sm |

- |

1.6 |

1.2 |

2 |

2.3 |

44 |

5575 |

3x150 sm |

- |

1.8 |

1.4 |

2.5 |

2.5 |

49 |

7150 |

3x185 sm |

- |

2 |

1.4 |

2.5 |

2.7 |

53 |

8550 |

3x240 sm |

- |

2.2 |

1.5 |

2.5 |

2.9 |

59 |

10700 |

3x300 sm |

- |

2.4 |

1.6 |

2.5 |

3.1 |

65 |

12925 |

3x400 sm |

- |

2.6 |

1.6 |

3.15 |

3.4 |

74 |

16900 |

3x500 sm |

- |

2.8 |

1.8 |

3.15 |

3.6 |

81 |

20650 |

Three cores+1(Galvanized steel wire armoured)

_clip_image002.jpg)

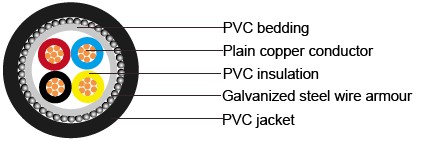

Four cores(Galvanized steel wire armoured)

Nominal Area |

Approxonductor Diameter |

Nominal Insulation thickness |

Nominal beddingthickness |

Nominal Steel Wire dia. |

Nominal Sheath thickness |

Approx.Overall Diameter |

Approx.Weight |

mm² |

mm |

mm |

mm |

mm |

mm |

mm |

Kg/Km |

4x4 re |

2.3 |

1 |

1 |

1.25 |

1.8 |

19 |

790 |

4x4 rm |

2.6 |

1 |

1 |

1.25 |

1.8 |

20 |

825 |

4x6 re |

2.8 |

1 |

1 |

1.25 |

1.8 |

21 |

925 |

4x6 rm |

3.1 |

1 |

1 |

1.25 |

1.8 |

21 |

975 |

4x10 re |

3.6 |

1 |

1 |

1.25 |

1.8 |

23 |

1175 |

4x10 rm |

4 |

1 |

1 |

1.25 |

1.8 |

24 |

1250 |

4x16 rm |

5 |

1 |

1 |

1.6 |

1.8 |

27 |

1750 |

4x25 rm |

6.3 |

1.2 |

1 |

1.6 |

1.8 |

31 |

2375 |

4x35 sm |

- |

1.2 |

1 |

1.6 |

1.9 |

31 |

2600 |

4x50 sm |

- |

1.4 |

1 |

2 |

2.1 |

37 |

3625 |

4x70 sm |

- |

1.4 |

1.2 |

2 |

2.2 |

40 |

4575 |

4x95 sm |

- |

1.6 |

1.2 |

2.5 |

2.4 |

46 |

6350 |

4x120 sm |

- |

1.6 |

1.4 |

2.5 |

2.5 |

50 |

7525 |

4x150 sm |

- |

1.8 |

1.4 |

2.5 |

2.7 |

55 |

8950 |

4x185 sm |

- |

2 |

1.4 |

2.5 |

2.9 |

60 |

10650 |

4x240 sm |

- |

2.2 |

1.6 |

2.5 |

3.1 |

66 |

13575 |

4x300 sm |

- |

2.4 |

1.6 |

2.5 |

3.3 |

73 |

16425 |

4x400 sm |

- |

2.6 |

1.8 |

3.15 |

3.6 |

83 |

21500 |

4x500 sm |

- |

2.8 |

2 |

3.15 |

3.9 |

91 |

26500 |